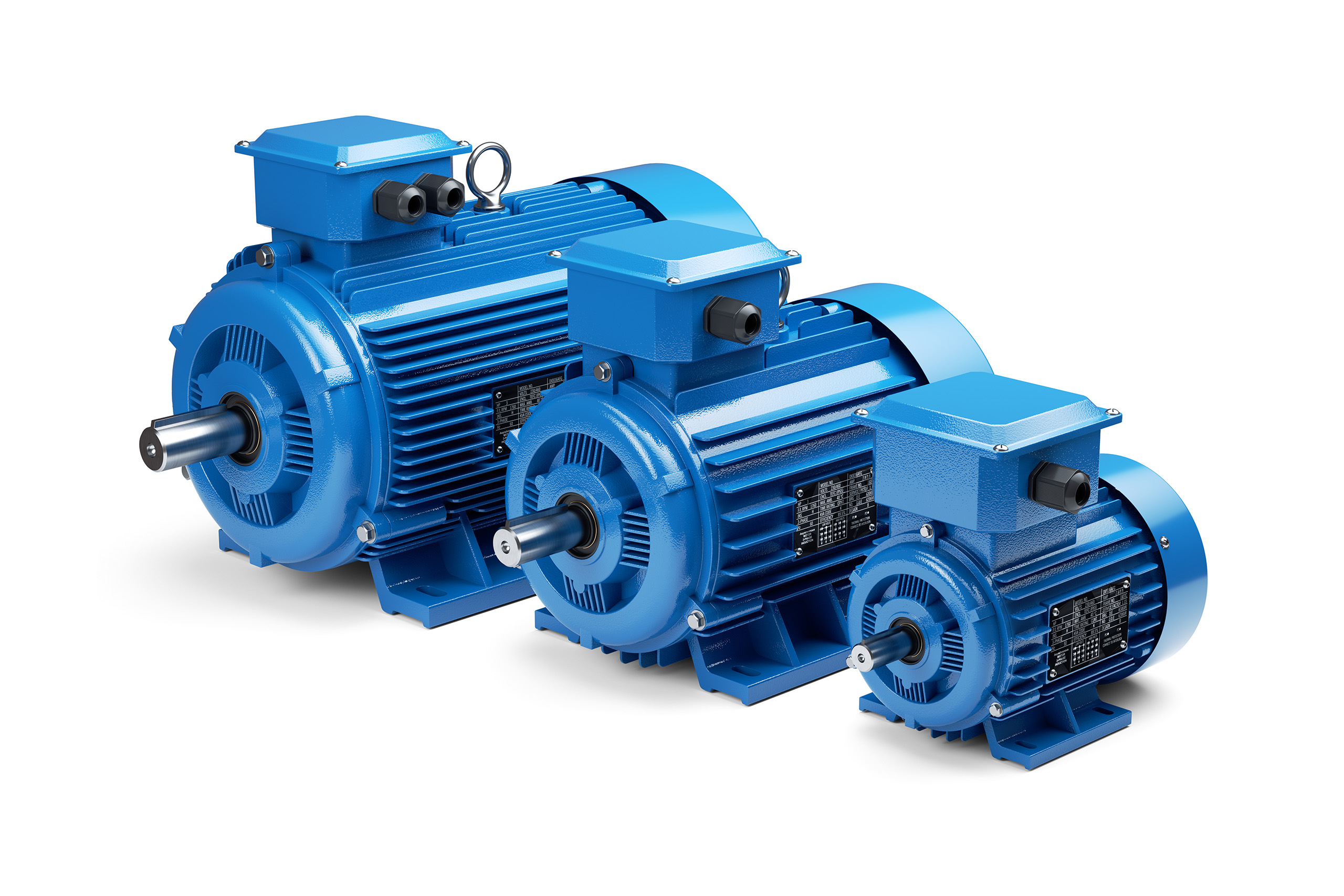

Circularity for industrial electric motors

45% of the world's energy use comes from industry's 300 million electric motors. Continued electrification will double this number by 2040. 80% of today's electric motors have a low energy class, and moving to a higher class would reduce energy use by 10%. With legislation and rising energy costs, motors will therefore be replaced, in parallel with electrification, allowing new production to more than double. Recycling of electric motor materials for remanufacturing is complex and costly, and therefore there is an outflow of e.g. Cu, Fe and Si. Therefore, circularity is required via optimised materials adapted for recycling, new motor design, and utilisation of existing machines as spare parts. The project will investigate how - material selection for electric machines can be optimised - motor design should be done for optimised operation, service and recycling - spare motor stocks can be coordinated to reduce material consumption - such a deal will be economically as well as climate and environmentally sustainable.